Prototype baseboard

From the outset our aim was to create baseboards that are light in weight, quick to assemble at exhibitions and do not require bolts to join.

This is the original prototype model of a baseboard joint seen from the rear. The lower section is the top part of a supporting leg that takes the weight of two baseboard ends. At the rear (front right of photo) you can just make out the case clip used to hold boards together. At the back of the photo can be seen part of the supporting beam that runs the whole length of the layout, this has two purpose, one is strength to the layout and a location point for the front lower facia panels. Nearer the camera is the track bed beam.

The same prototype viewed from the front.

Over a period of evenings this design was revised into a final version we could begin to construct.

Construction

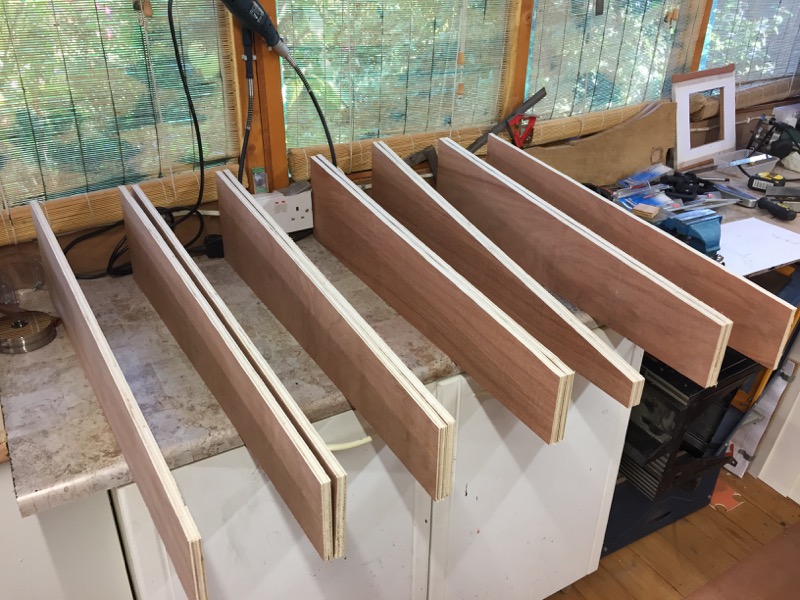

Baseboard construction will use softwood, plywood and foam. We started with a list of timber that needed to be machined to size. This was done using a band saw, bench saw, bench sander and planer thicknesser.

After a few hours we had this lot.

Alongside this we made baseboard/support locating toggles.

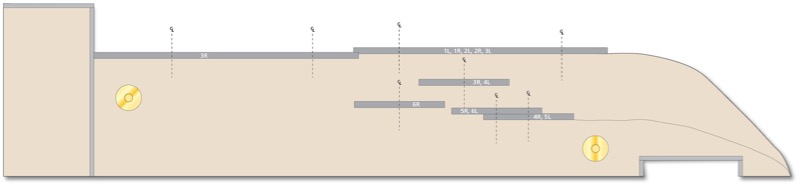

A baseboard end master template was drawn to show land profiles, track bed heights and track centres, along with locating dowel positions and under board front beam location. In this cross section can be seen the front lower beam and the rear box beam that runs the whole length of the layout.

From this a plywood jig was cut and used as a guide for all end board construction. Here seen on top of the precut end board pieces.

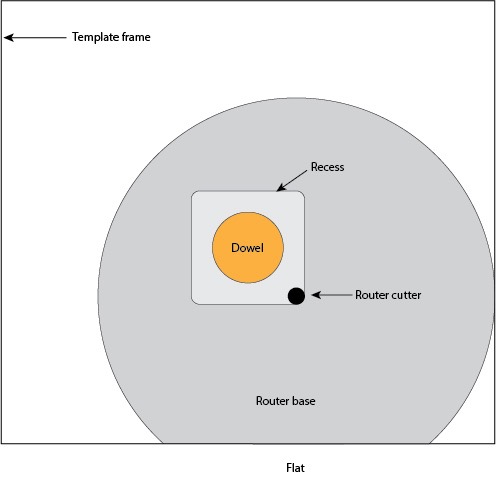

At the same time a jig for routing the location dowel positions was drawn up. The flat bottom grey circle represents the base plate of the router, the black circle is the router bit. It should become clear later how this works

These are the alignment dowels we are using.

To save time we had the timber yard cut some of the plywood to the cutting list we supplied.

Then we rough cut the end profile boards.

Using a jig (the metal plate) and the template (plywood panel) to drill the holes for the baseboard toggles mounting plate bolts. We used spare brass locating dowel plates to accurately locate the plywood template.