Originally the layout was to be fed by a fiddle yard and rather than hide this away, we would be making a feature of it, thereby increasing the viewing footage of the layout.

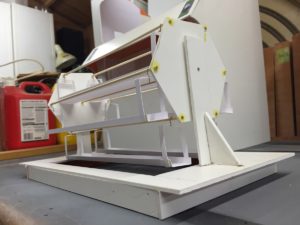

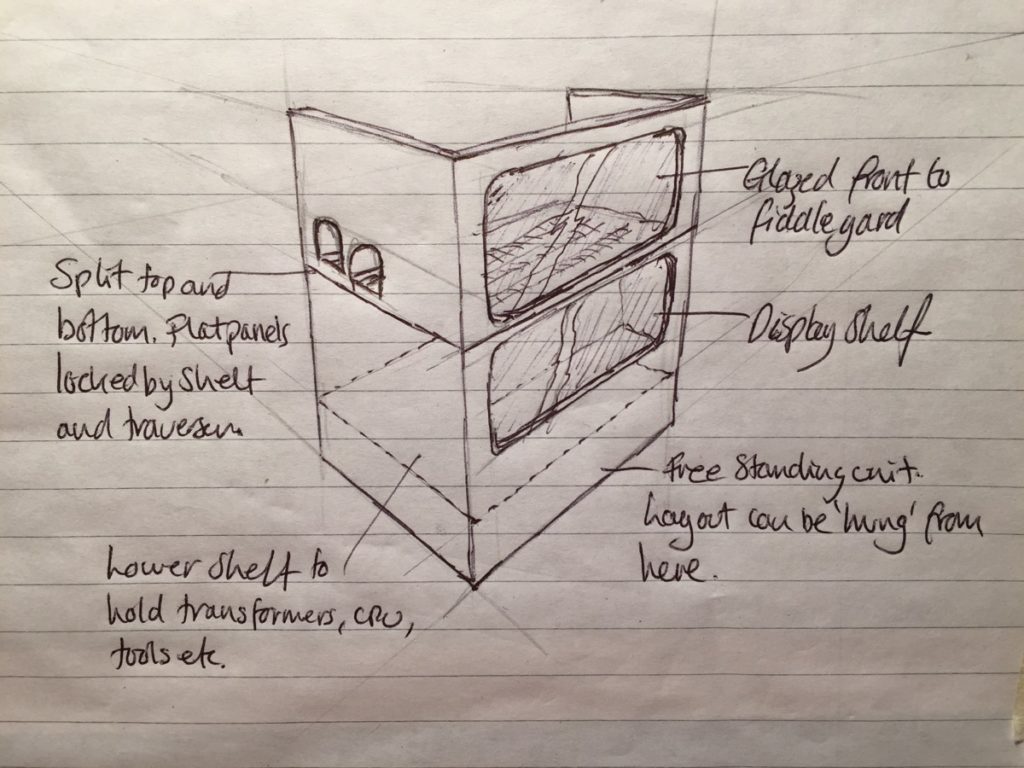

This is the initial concept sketch.

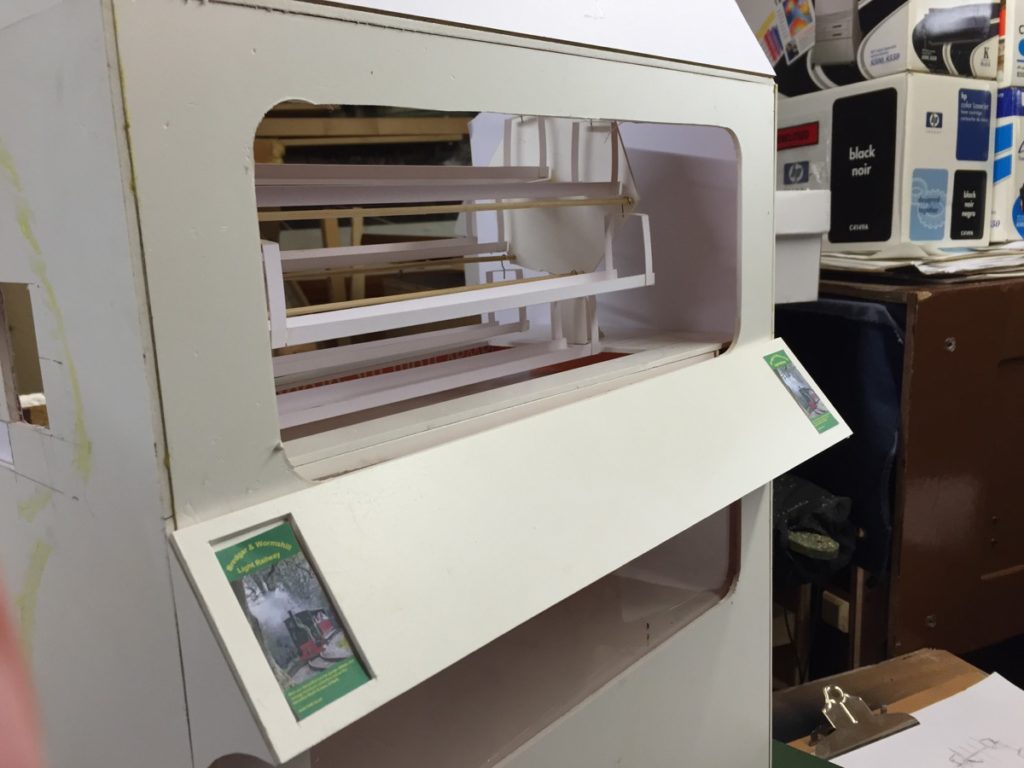

As a contrast to the layout this will be mainly of a flat panel construction, with clip together assembly. The fiddle yard itself will be a traverser, hopefully in a powered format with push button track positioning using stepper motors. Viewing will be through the upper glazed panel, the interior of the fiddle yard will be mainly white surfaces and aluminium, hopefully all of display case quality and lit appropriately to enable show visitors to see the stock close up.

The lower panel will be a static display shelf behind a glazed panel. inside at the back at low level will be a shelf to hold all electrics and tools, this will basically be a wide flat box with a lid, this will fix to the front and sides and help form the fiddle yard box structure, from this the layout will be hung.

This will be the first thing assembled at a show and the last thing disassembled, well that was the theory.

A model was constructed to prove the idea.

All change!

Our initial thought was to have a traverser fiddle yard, be that manual or powered.

When we started drawing full size plans it became obvious this would be a bit of a beast in this scale, requiring a far amount of space behind the layout to get the full travel. With this would also come the leverage effect due to the weight of stock.

Thinking caps on, a fresh cup of tea and we set to work devising an alternative.

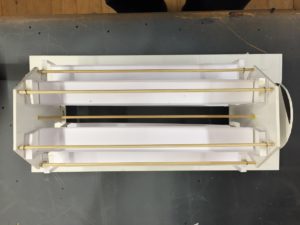

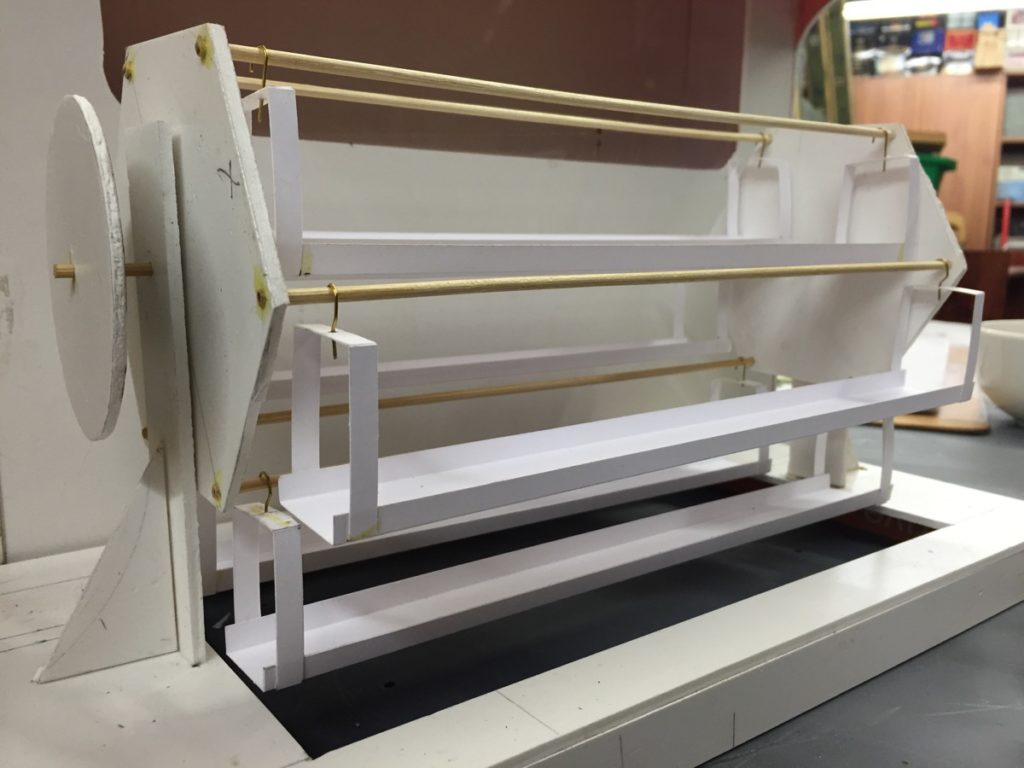

We present to you the RotaYard rotisserie fiddle yard MK1. A quarter scale mock up was constructed to get a feel if this could be viable. It seems we can get a six road fiddle yard in less than the baseboard depth and fully contained within the last layout board. We have the potential for pairs of parallel exit roads at each end if required.

- RotaYard end detail

- RotaYard view along a gondola

- RotaYard

- RotaYard arial view

It will fit quite nicely in the fiddle yard cabinet.

We worked on various ideas for track locking to ensure trouble free operation, with the intention for the rotary yard to be operated by six buttons, with electrical gizmos deciding which is the best direction to rotate to get the track in position in the shortest time, along with controlling acceleration and deceleration of the rotation.

Possibly the use of power location pins, but more likely to be powered side clamps.

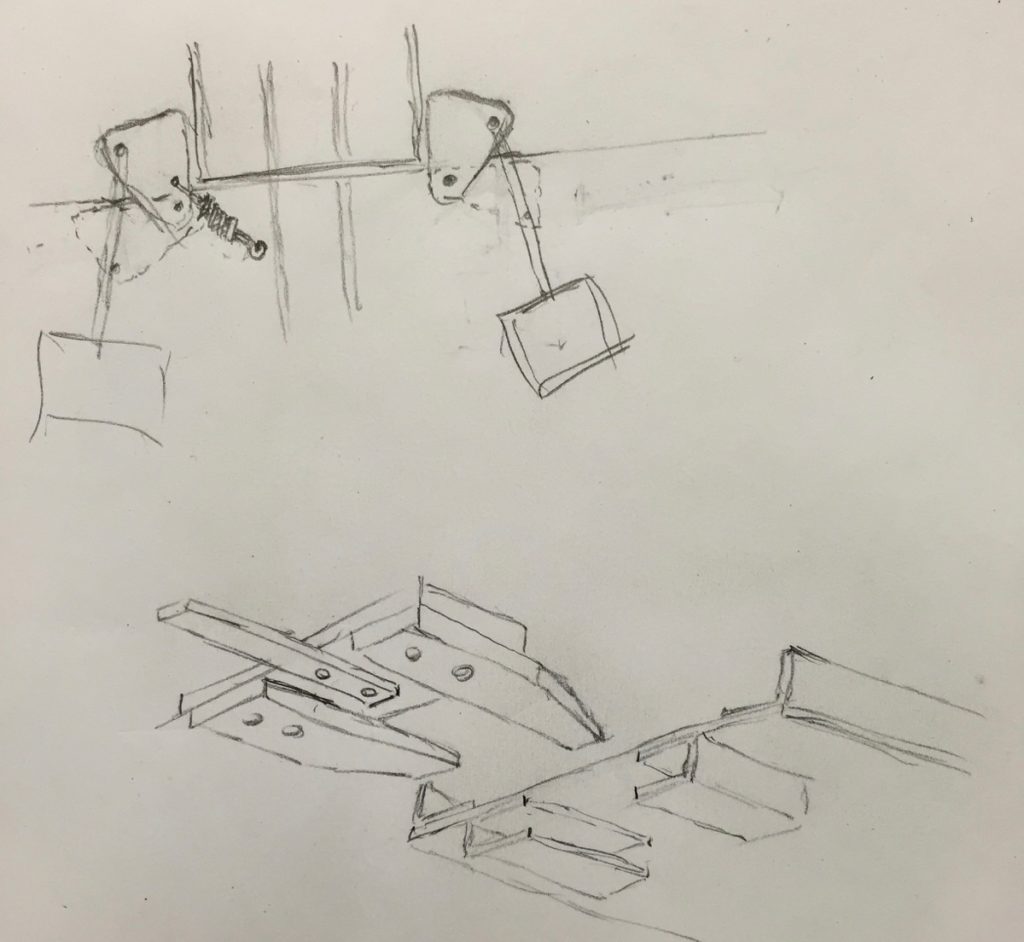

Thoughts also turned to safety devices to prevent stock rolling if the boards are not entirely level, so a full size mock up was made of the a solution to prove the concept.

We went through many complex solutions, but many cups of tea later things were greatly simplified and this could well be the solution activated by the locating clamps.

A counter balance weight pivots a bar up which only has to prevent stock rolling off the edge.

This will all be refined to the minimum required to achieve the aim.

To see how we developed the concept see here.